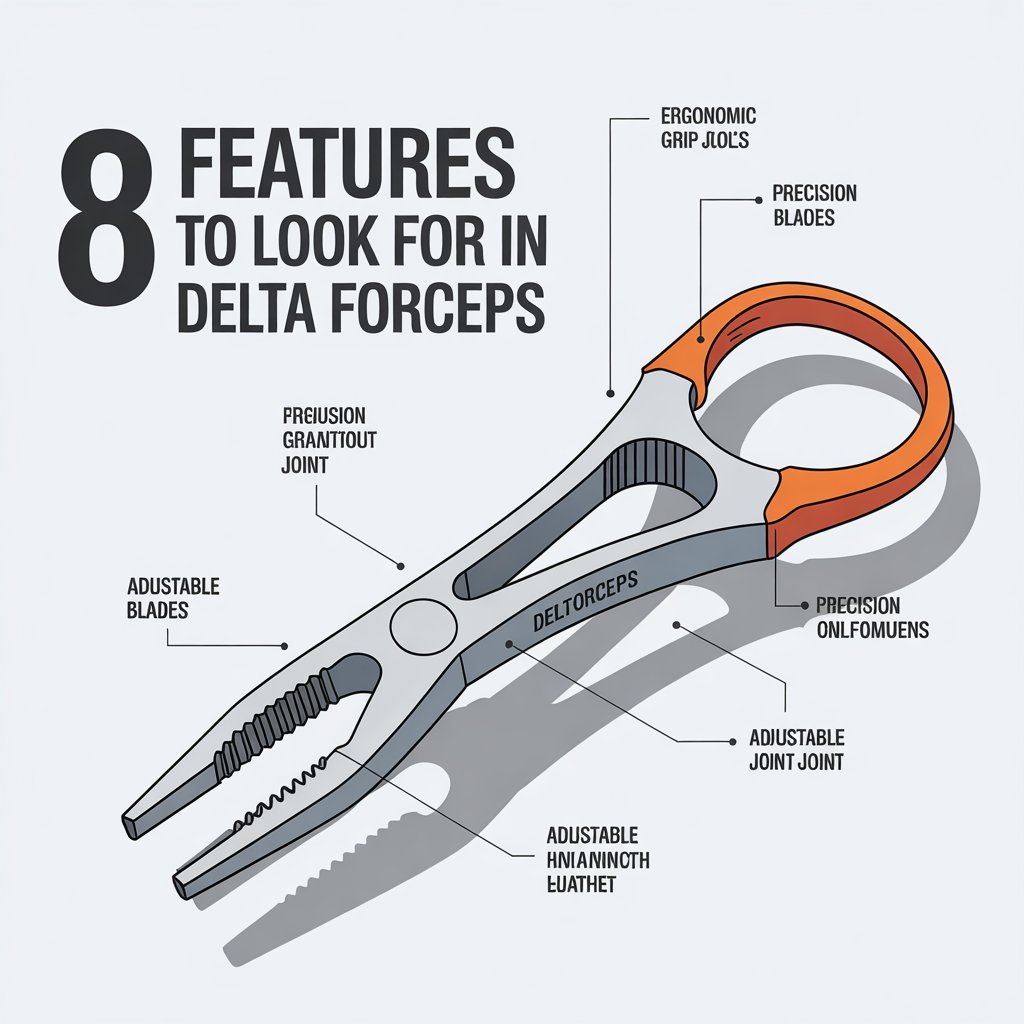

8 Key Features to Search for in Delta Forceps: A Full Guid

When precision counts in surgery, the right tool makes all the difference. One of the most essential tools in a surgeon’s toolkit is Delta Forceps, delicate instruments for precise tissue handling, suturing, and gripping in a variety of medical interventions. Whether you are an experienced surgeon, a medical student, or a procurement officer, recognizing the essential features of quality Delta Forceps guarantees peak performance, patient safety, and procedural efficacy.

In this comprehensive guide, we will walk you through the 8 essentials to look for when choosing Delta Forceps, provide real-life tips from surgery experts, and answer FAQs so you can make an educated decision.

1. High-Quality Stainless Steel Construction

Why It Matters

Delta Forceps should be long-lasting, resistant to corrosion, and sterilizable so they can take repeated exposure to surgical settings. German stainless steel is the benchmark, providing:

Superior tensile strength for enduring performance.

Rust resistance, important for hygiene maintenance.

Autoclave compatibility, for safe sterilization between procedures 16.

Personal Insight

A colleague once mentioned that a lower-quality, cheaper forceps rusted after being used a few times for sterilization, creating contamination risks. Spending money on medical-grade stainless steel prevents this.

2. Precision Tip Design (Serrated vs. Smooth vs. Toothed)

Key Considerations

Delta Forceps are available with varying tip designs, each designed for specific applications:

Serrated tips – Offer a strong grasp without causing too much tissue destruction (optimal for vascular surgery).

Toothed tips (1×2, 2×3, etc.) – Increase accuracy in fine surgeries (e.g., plastic or ocular procedures).

Smooth tips – Suitable for manipulating thin tissues where little trauma is needed 17.

Real-World Applicatio

While performing a laparoscopic operation, the surgeon observed that Debakey Vascular Forceps (Delta Forceps) with fine serrations provided improved vessel control without slippage 1.

3. Ergonomic Handle Design

Why Comfort Matters

Extended surgeries require instruments that minimize hand fatigue. Consider:

Finger ring handles to improve maneuverability.

Light weight (titanium is a great option for microsurgeries).

Textured grips that don’t slip when it matters most 67.

Anecdote from the OR

A neurosurgeon once changed to ergonomic Delta Forceps after developing wrist strain during a 6-hour craniotomy—productivity and comfort greatly improved.

4. Locking Mechanism (Ratcheted vs. Non-Ratcheted)

Differences in Functionality

Ratcheted forceps (e.g., Allis or Babcock Forceps) lock, enabling hands-free tissue retention.

Non-ratcheted (thumb forceps) provide faster release, best for dynamic adjustments 110.

Surgical Scenario

In obstetric deliveries, ratcheted forceps offer secure fetal head traction, while non-ratcheted types enable rapid repositioning if necessary 9.

5. Balance of Length and Weight

Ideal Sizing

Delta Forceps are between 4.75″ (tender microsurgery) and 9.5″ (deep cavity operations). Key considerations:

Short forceps (5-6″) for detailed work (e.g., ophthalmology).

Long forceps (7-10″) for orthopedic or abdominal surgery 16.

Case Study

An 8″ DeBakey Forcep was favored by a cardiac surgeon for aortic procedures due to ideal balance of control and reach.

6. Specialized Coatings (Tungsten Carbide, Diamond Dust)

Increased Performance

Grip on smooth tissues is enhanced by diamond-dust coating.

Tungsten carbide tips provide extreme durability for repeated use 6.

Industry Trend

Increased use of diamond-coated forceps in laparoscopic and robotic procedures because of their non-slip reliability.

7. Sterilization and Maintenance Compatibility

Best Practices

Autoclave-safe materials (stainless steel, titanium).

Inspection protocols – Check for misalignment or wear after each cycle 310.

Lesson Learned

A surgical center lowered instrument failure rates by instituting monthly forceps inspections.

8. Manufacturer Reputation & Certifications

Why Brand Trust Matters

FDA/CE-certified brands (e.g., Ger MedUSA, Surgi Right) guarantee compliance.

Warranty and support – Trustworthy manufacturers provide replacements for defects 17.

Procurement Tip

A hospital procurement manager offered that using ISO-certified suppliers reduced complaint rates for faulty instruments by 40%.

FAQs on Delta Forceps

1. What are Delta Forceps utilized for?

They are mainly utilized in grasping, holding, and manipulating tissues in general, vascular, and microsurgeries 17.

2. How do I select between toothed and non-toothed forceps?

Toothed (1×2, 2×3 teeth) – Ideal for thick tissues (fascia, tendons).

Smooth/serrated – Perfect for fine structures (vessels, nerves) 1.

3. Are Delta Forceps reusable?

Yes, if autoclave-safe stainless steel is used, but check for wear regularly 310.

4. How do De Bakey and Adson Forceps differ?

De Bakey – Fine serrations, employed in cardiovascular surgery.

Adson – Toothed tips, frequently used in plastic and general surgery 17.

5. Where can I purchase high-quality Delta Forceps?

Reliable vendors such as Ger Med USA, Surgi Right, and Peak Surgical provide certified alternatives 1710.

Last Thoughts

Picking the right Delta Forceps is a mix of material quality, ergonomics, and task-specific design. By emphasizing these 8 features, surgeons can improve surgical accuracy, limit fatigue, and enhance patient results.

Have you come across a revolutionary forceps design in practice? Share your experiences below!

Sources:

Ger Med USA (Types of Tissue Forceps) 1

Surgi Right (Forceps Types Guide) 7

Peak Surgical (Surgical Forceps Overview) 10

FitCoding (Forceps Care & Uses) 3